air tightness test of boiler|boiler performance testing requirements : companies tightness testing, the tests must be capable of detecting a leak of 0.10 gallon per hour with a probability of (at least)95%, while operating at a false alarm rate of 5% or less. A large number of test devices and methods are reaching the market, but little evidence Resultado da Notícias do Grêmio. Todas as notícias. Acompanhe as últimas notícias do Grêmio, próximos jogos, prováveis escalações, Brasileirão Série A, .

{plog:ftitle_list}

web0:00 / 14:58. DEPILANDO A VIRILHA SOZINHA EM CASA. Carla Damares. 17.1K subscribers. Subscribed. Like. Share. 1.7M views 4 years ago #beleza #Virilha. #beleza .

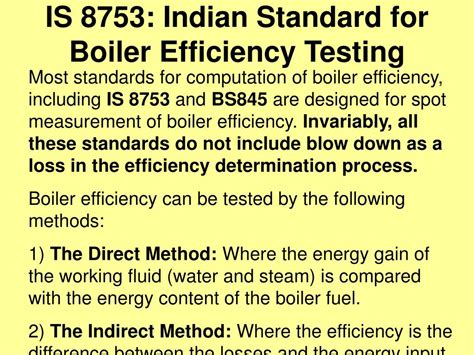

Conducting a boiler performance test can be for understanding the current level of performance of the boiler, for any trouble shooting of the boiler for performance deviations, and for proving the performance guarantees. Steam lines are tested hydraulically with water as per code. Gas tightness or air tightness test are tested on boiler & duct side with smoke bomp to ensure that there is no .tightness testing, the tests must be capable of detecting a leak of 0.10 gallon per hour with a probability of (at least)95%, while operating at a false alarm rate of 5% or less. A large number of test devices and methods are reaching the market, but little evidence Gas tightness or air tightness test are tested on boiler & duct side with smoke bomp to ensure that there is no leakages in Boiler wall throgh fins. Register to Reply: sajipv. Member. Join Date: Jun 2009. Posts: 6 #3. Re: Gas Tightness & .

In the realm of commercial gas safety, ensuring the tightness of gas installations is a crucial step. The Commercial Gas Tightness Test Procedure is an essential process that ensures the integrity of gas systems in commercial buildings. This comprehensive article will guide you through the entire test procedure, explaining the necessary steps, equipment required, and standards to .

Pre-commissioning checks also include other tests necessary to ensure proper performance of the boiler during commissioning and thereafter. These tests carried out are. Gas tightness test; Air tightness test on boiler and connected ducts; Gas distribution test in electro static precipitator (ESP) Air load test in ESPThe performance test in a boiler evaluates the practically achievable boiler efficiency. Performance tests are also carried out to prove boiler guarantees. As guarantees involve contractual conditions, the procedure involved are . The flue gas measurement by Orsat must also be organized - leakage of air into flue gas during sampling is a .

How is an air tightness test carried out? To complete an air tightness test, the Croydon engineer will need access to an empty dwelling. The engineer will need access to an external door (approximate size 2.1m high x 0.9m wide) and .Air Tightness Testing – €250 – As well as providing a fast and accurate Air Tightness Test we are happy to give free advice regarding Airtight Construction Details. . ensuring there is a good seal around boiler flue pipes where they pass through the external wall/ceiling; .

boiler performance testing requirements

Unlock the essential knowledge of boiler hydrostatic testing with our comprehensive guide. Discover the step-by-step procedures, requirements, and industry best practices for conducting this crucial test to ensure the utmost safety and reliability of your boiler system. Learn about the importance of hydrostatic testing in identifying potential weaknesses, .Water tube Boiler Commissioning Refractory dry out Air tightness test Gas tightness test Alkali Boil out Passivation Steam blowing Safety valve setting Testing of protection & interlocks Calibration of instruments . Pre-commissioning Activities The following activities are to be carried out before commencing trial operation of the boiler .How is an air tightness test carried out? To complete an air tightness test, the Blackburn engineer will need access to an empty dwelling. The engineer will need access to an external door (approximate size 2.1m high x 0.9m wide) and .

Table 1/2.2 Additional Testing New Requirements for Vessels or Tanks of Special Service 1/3.5.5b Special Periodical Surveys-Revised-old 1/3.1.5b Commencement 1/3.5.7a Continuous Surveys Revised-old 1/3.1.6a 1/3.5.11b Underwater Inspection in lieu Revised-old 1/3.2.1b of Drydocking Survey 1/3.5.17a1 Water-tube Boilers for Revised-old 1/3.15.1a1 .

Agency is charged by Congress with protecting the Nation's land, air, and water resources. Under a mandate of national environmental laws, the agency strives to . In the case of tank or pipeline tightness testing, for example, this will mean testing under both 0.0gal/h and 0.1- 0-gal/h leak rates. In the case of groundwater monitoring, this .

Air Tightness Testing, Air Leakage Testing, Air pressure Testing Swinton - Greater Manchester . Having been in the energy business since 2007, our gained knowledge puts us in an exceptional position to supply support and advice for all your Domestic or Commercial needs. . Ensure there is a good seal around boiler flue pipes. When Do I Need an . An air tightness test is defined as a procedure to determine the air tightness of a given pipeline at air tight joints and U traps. In order to maintain the pressure in the pipeline, a certain amount of air has to escape. Thus, an air tightness test also determines the percentage of lost air over a certain time period.Air pressure testing, also known as air tightness or air leakage testing, is a process used to determine the uncontrolled airflow and unwanted drafts in a property that could result in heat loss. . • All service penetrations, loft hatches .Air tightness testing has importance in industrial environments where in compressed air systems leaks account for a high percentage of energy loss. These losses can effectively be reduced by locating and repairing of leaks. Furthermore, tightness is a criterion for the quality of different kinds of seals and joints. For leak

The air tightness test determines the amount of air leakage in cubic metres per square metre of internal surface area of the building m3. Or, to put it simply, air tightness testing measures the amount of air that escapes through the gaps or building fabrics.In the intricate world of commercial gas systems, the processes of gas pipework tightness testing and purging stand as cornerstones for ensuring safety and compliance. Let’s delve into the essential aspects of these procedures: New Installations Steps: Installation of pipework. Strength testing with air. Tightness testing with air. Purging .How is an air tightness test carried out? To complete an air tightness test, the West Yorkshire engineer will need access to an empty dwelling. The engineer will need access to an external door (approximate size 2.1m high x 0.9m wide) and . Air Testing – also known as Air Tightness Testing, Air Permeability Testing, Air Leakage Testing, and Air Pressure Testing – measures the amount of air escaping through cracks and gaps in the building envelope. A more airtight building translates to better energy efficiency, lower heating and cooling costs, and a more comfortable living .

Boiler condition survey and witness commissioning of commercial central heating boilers; Determination of combustion and ventilation air requirements, NOX, CO, CO2, excess oxygen, flue gas temperature and combustion efficiency; Gas tightness testing and site assessment of boiler flues and checking for compliance with the building regulationsAir Tightness Testing is a requirement for all new buildings, whether residential, commercial or public, under Part L of Building Regulations. It forms part of the SAP calculation for new homes and part of the SBEM calculation for any building that isn’t residential. . Ensure there is a good seal around boiler flue pipes. When Do I Need an .tightness testing methods must be capable of detecting a 0.10 gallon per hour leak rate with a probability of detection of at least 95% and a probability of false alarm of no more than 5%. It is up to tank owners and operators to select a method of leak detection thatHow is an air tightness test carried out? To complete an air tightness test, the Grimsby engineer will need access to an empty dwelling. The engineer will need access to an external door (approximate size 2.1m high x 0.9m wide) and .

Comprehensive tightness testing & purging. Annual checks, compliance, efficiency, safety ensured. 07869 818968; . Boiler & Heating Services; Tightness Testing & Purging; . Proper purging of your commercial gas system is essential to eliminate any air or non-combustible gases that may compromise its efficiency or safety. Our experts .

Air leakage, then, is expressed as Xm./hr/m.@50Pa. This is the measure the Building Regulations in the UK uses. Alternatively, air change is measured as the rate the volume of air changes in the building per hour at 50 Pa. Air changes are expressed as Xach/hr@50Pa. This is the measure used by Passivhaus, for example.

good refractometer reading

good salinity refractometer

web23 de fev. de 2016 · O que é preciso para fazer topo de bolo? Para fazer um topo de bolo, além de escolher o melhor programa ou aplicativo para o seu caso, você também vai precisar dos materiais listados abaixo. papel fotográfico glossy ou papel couchê com gramatura de no mínimo 180g; tesoura de precisão ou máquina corte como a Silhouette .

air tightness test of boiler|boiler performance testing requirements